Capabilities

At GLC Industries, we are committed to offering high quality products and processes to solve our customers most difficult problems; through our commitment to our core values of excellence, capability, responsibility, and partnership, we aim to exceed our customers’ expectations every day.

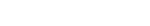

Machining

At GLC Industries, we understand that your machining needs won’t always fit into the typical machining shop’s comfort zone. Through experience with fixtures, jigs, prototypes, preproduction, and production run machining, our capabilities far surpass the industry standard. With technical expertise to expand as our customers’ needs change, we can remain a constant partner, growing alongside you as your business needs expand.

GLC Industries is committed to serving your needs because we understand that this is how long-term business relationships are developed. Give us an opportunity and we will guarantee your satisfaction.

Robotic Welding

GLC Industries has successfully incorporated robotic welding into many of our processes. Our manufacturing capabilities include a OTC 2 station, 7 axis digitally controlled Metal Inert Gas (MIG) weld robotic cell. This weld cell gives GLC the ability to manufacture a wide range of components in medium to high volumes, while repeating close tolerances part after part. Our versatility and quality precision allow us to consistently exceed customer expectations.

Welding

GLC provides GMAW (MIG Welding), GTAW (TIG Welding), and FCAW (Arc Welding) processes in low to medium volumes with capabilities in ferrous and non-ferrous material up to 1″ meeting AWS standards. These processes are achieved in an environmentally controlled booth.

Light Assembly

In today’s manufacturing environment, our customers are continually seeking to reduce their costs. To respond to this challenge, GLC Industries offers not only fabricated components, but the service of assembly as well to add value to your bottom line. As your one-stop- shop, GLC will manufacture, procure, and/or assemble all components needed, simply providing you with the finished product you need.

GLC Highlight: Quality Management System Certification

GLC has been certified for AS9100D including ISO 9001:2015 Certification

November 22, 2017: After a thorough audit process with Eagle Registrations Inc., GLC’s Quality Management System has been certified for AS9100D including ISO 9001:2015 Certification.

The formal certificate of Registration states “this assessment was performed in accordance with the requirements of AS9104/1:2012 EAGLE registrations.” The scope of this registration includes Aerospace Machining & Turning, Robotic Welding, and Manufacturing.

The GLC team is very proud of this achievement and looks forward to contributing this level of quality management standards to all existing projects and toward future success for our valued customers!

GLC’s CNC Turning & Milling Centers

Mitsubishi MCV1000A

Z axis 21”/Y Axis 20”/ X axis 40”

Tolerance 0.001”

20-Tool Changer

Haas VF-E

Z Axis 20”/Y Axis 16”/X Axis 20”

Tolerance 0.001”

20-Tool Changer

2x Mori Seiki CL200B Lathes

12-Tool Changer

Cutting Diameter 16”

Cutting Length 12”

Thru Spindle Bore 2-2/12”

Sharp SC2412

Z Axis 18”/Y Axis 12”/X Axis 24”

Tolerance 0.001”

10-Tool Changer

Fadal VMC3016

Z axis 16”/Y Axis 16”/ X axis 30”

Tolerance 0.001”

12-Tool Changer

Prototrac Op2

ZAxis 20”/Y axis 15” X axis 20”

Tolerance 0.001”

8 tool changer

DMG Mori NLX2500Y 3 Axis

Main Spindle with Tailstock

Cutting Diameter 366mm/14.4”

Cutting Length 705mm/27.7”

Bar Feed 80mm/3.1”

Fadal VMC 4020

Z Axis 20”/Y Axis 20”/X Axis 40”

Tolerance 0.001”

20-Tool Changer

Hardinge Talent 8/52 Lathe

Main Spindle with Tailstock

12-Tool Changer

Cutting Diameter 1-5/8”

Cutting Length 15”

Hardinge Quest 8/51 Lathe

Main Spindle & Sub Spindle capable

6 live tooling slots (12-Tool Changer)

Cutting Diameter 305mm/12”

Cutting Length 521mm/20.5”

Spindle Bore 60mm/2.36”

Leadership

Byron Craig, Managing Partner

Byron Craig is the Managing Partner of GLC Industries. Since the formation of GLC in 2005, Mr. Craig has guided GLC by growing it from a 3,500-square foot garage with only light machining capabilities into a machining production unit with an ever-growing list of additional capabilities.

In addition to his responsibilities at GLC, Mr. Craig has taken on a business development role within Boneal, Inc. In this capacity, he will work towards the goal of expanding the company’s Kentucky manufacturing business.

Mr. Craig has accumulated over twenty-five years of manufacturing experience throughout his career. Prior to establishing GLC Industries, he worked at Boneal, as well as many reputable companies including Whirlpool Corp., Toyota Motor Manufacturing, and UPS.

Mr. Craig attended both the University of Cumberland and University of Kentucky.